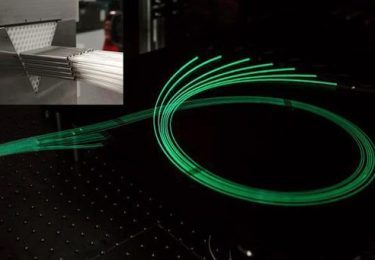

aeroGAIN-ROD – high-power ytterbium rod fiber gain modules

The aeroGAIN-ROD module is the ultimate high-power fiber amplification module for ultrafast pulsed lasers. With its 3300 µm2 mode field area and high pump absorption, it gives you a power handling previously only available in solid-state configurations.

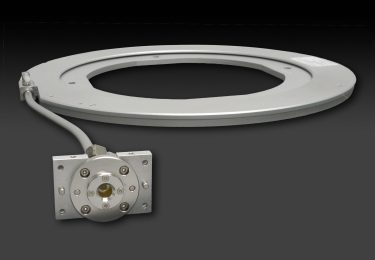

The rugged aluminum body makes the module easy to handle and mount for OEM integration and scientific laboratory setups.

Key Features

Diffraction-limited beam quality

High peak power damage threshold

Compact format

High NA pump cladding

Optimized for 1030-1040 nm range

PM and non-PM amplification

Real single-mode amplification

The aeroGAIN-ROD modules offer true single-mode amplifications at power levels previously reserved for multimode systems. True single-mode amplifications have a range of advantages compared to multimode systems:

- Better output stability

- Excellent beam quality

- No need for tight coiling

The excellent mode quality and easy coupling make the aeroGAIN-ROD module an ideal gain medium for high-power amplifiers. The rugged aluminum body makes the module easy to handle and mount for OEM integration and scientific laboratory setups.

Integrated water cooling with quick coupling ensures efficient thermal management and a long maintenance-free lifetime of thousands of hours.

The pump light is guided by our proven air-clad technology, with high reliability, high damage threshold, and large NA. The modules come standard with high-power AR-coated end-caps.

Want more details?

If you want more details about typical performance and how to couple signal and pump light, we have some application notes for you.

Read more about test procedures and typical performance when you use the aeroGAIN-ROD 2.1 for amplifying ps pulses in a single-pass configuration.

Learn how to couple signal and pump light to and from a simple reverse-pumped amplifier based on an aeroGAIN-ROD fiber.

Specifications

1) Under nominal operation: Seed level 5 W @ 1030 nm, 976 nm pumping, signal power ≥ 100 W

2) MFD decreases with thermal load. The actual reduction will depend on the system parameters. A typical reduction is less than 0.1 %/W (signal power).

1) We recommend using DI water containing an anticorrosive additive to protect the aluminum cooling circuit. Required

water flow and water temperature depending on the actual optical system parameters.