Let’s share the knowledge

We are continuously exploring the ultrafast processing of novel materials and are eager to share our knowledge to support your application development.

We can make tests and proof of concept in-house and apply our knowledge and skillset to your project, offering support and advice to enhance your results.

What do you want to do?

Regardless of your requirements, we are happy to offer advice and explore with you whether your laser micromachining requirements are ablation, drilling, cutting, glass cleaving, scribing, marking, engraving, welding, ophthalmology, opto-stimulation or surface functionalization of metals, ceramics, brittle transparent materials or organic materials.

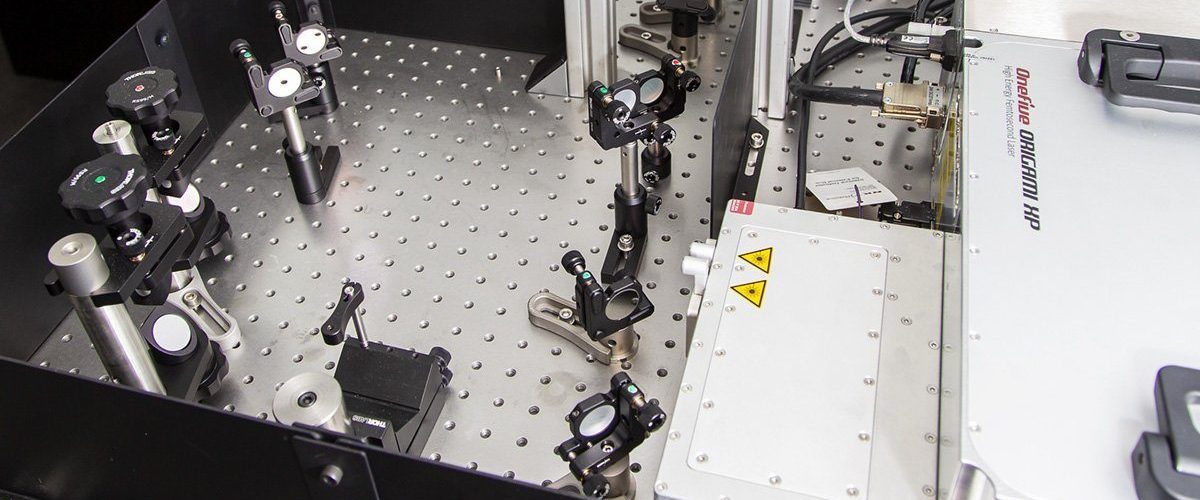

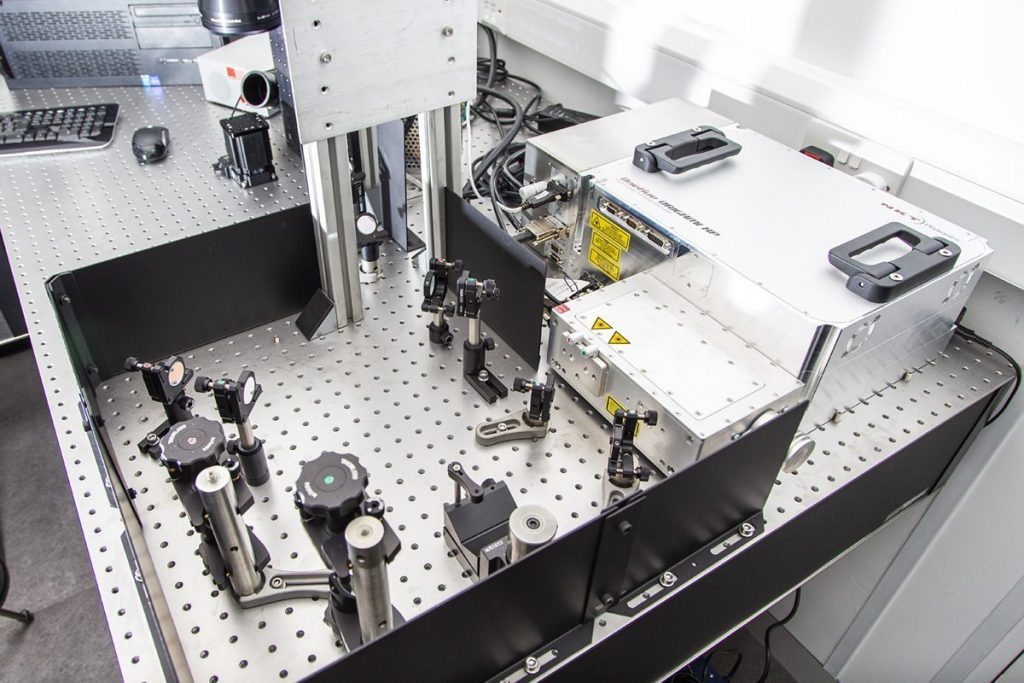

Industry-leading equipment ensures the best result

Currently, we have two micromachining set-ups equipped with a wide range of galvo scanners, telecentric f-theta lenses, beam expanders, XYZ motion stages with a dual-axis position synchronized output (PSO) capability, various scanner control cards, and scanner software, and our versatile high-performance compact ultrafast lasers. With the right combination of optical components, we can focus laser beams down to a spot size of <5 µm.

Material processing is achieved with high accuracy, using nothing but industry-leading equipment from Aerotech, Newport, Zaber, Scanlab, Raylase, and NIKON. Furthermore, high-resolution CCD camera-based optical microscopy is employed to provide a detailed analysis of processed samples.

With a wide range of microscope objectives combined with the motorized XYZ stages and image stitching or automated Z-axis acquisition features, we can create a detailed 3D profile of features to analyze the results. If needed, access to SEM and TEM analysis equipment is available for exploratory material analysis.

Micro-machining for every industry

Our ultrafast lasers are capable to process virtually any material from metals, ceramics, glass, polymers, organic materials, and even composites. We can configure our setup easily to meet your micromachining needs whether you’re involved with display manufacturing, medical device manufacturing, automotive, aerospace, or semiconductor and microelectronics.

What can we explore for you?

Lab equipment

- Galvo scanners

- Telecentric f-theta lenses

- Beam expanders

- XYZ motion stages (dual-axis position synchronized output (PSO) capability)

- A range of scanner control cards and software

- High-resolution CCD camera-based optical microscopy

- Our high-performance compact ultrafast lasers

- Supporting optical components

- Access to Scanning Electron Microscopy and Transmission Electron Microscopy

Address

NKT PHOTONICS LTD

20 Compass Point, Ensign Way

Southampton, SO31 4RA, UK