The Capasso Group – a research team at the Harvard John A. Paulson School of Engineering and Applied Sciences, Harvard University – has developed broadband achromatic RGB metalenses and has used an NKT Photonics SuperK white light fiber-coupled laser to validate the performance.

Increasing meta-optic complexity

Meta-optics[1] has achieved major breakthroughs in the past decade. In short, multiple optical functionalities depending on, for example, wavelength, polarization, spin and angles of incident light, can all be engineered into a single flat optic, all without the bulk of classical optics.

Among the prerequisites to realizing an effective meta-optic are:

- its accurate performance simulation

- the designed device can be manufactured within the bounds of available fabrication techniques.

Approaches that, in particular, address these two issues from the outset promise a new paradigm for applications[2]. Perhaps one additional caveat with increasing optic complexity is the concomitant diversification in test requirements. Where, for example, a meta-optic is to provide broadband achromatic performance, the simulation needs to be validated with test & measurement across the target spectral range. Broadband, fiber-coupled laser sources can provide consistent beam parameter performance across such spectral ranges.

High-performance meta-optics for VR/AR

Li et al[2] demonstrate the use of a computationally efficient, inverse design approach for complex mm or even cm-scale 3D meta-optics[3], that can naturally account for fabrication constraints.

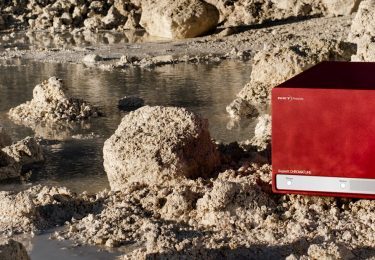

To demonstrate their approach, the group first simulated and then fabricated two 2-mm-diameter RGB achromatic metalenses onto fused silica substrates, and subsequently utilized these elements within a fiber scanning near-eye VR and an AR imaging configuration.

Large-scale meta-optics can be fabricated onto or into a surface using nanoimprint lithography techniques or – as in this particular case – with e-beam writing. CMOS-compatible fabrication techniques can also be employed[4].

NKT Photonics’ SuperK white light lasers are a boon for spectral performance validation for the many and diverse meta-optic projects undertaken in our group.

Harvard John A. Paulson School of Engineering and Applied Sciences, Harvard University

Characterization at multiple wavelengths

Validation of the imaging performance was performed at the RGB values at the extremes of the intended color gamut – in this case, 470, 548, and 648 nm. For this, the authors used an NKT Photonics SuperK white light fiber-coupled laser and a SuperK VARIA tunable filter to yield minimal linewidth (≈10 nm) at each wavelength.

By combining outputs of separate and individual laser diodes at the RGB wavelengths (in this case, each with ≈1 nm linewidth), synthesized yellow, cyan, and magenta “wavelengths” could also be reached.

For the VR & AR proof-of-principal set-ups, the SuperK white light fiber-coupled laser was again used, and again at the intended RGB wavelengths. Via temporal and spatial modulation of separate fiber-coupled RGB channels in multi-levels, the authors were able to demonstrate single, 3- and 7-color 3D-effect VR images.

Summary

The key take-away from the research is the capability for sharp achromatic imaging and displaying across a broad spectral range, utilizing a meta-optic design approach that significantly reduces computational overhead whilst simultaneously accounting for fabrication limits.

The authors plan to explore the physics, design methods, as well as fabrication techniques that together enable the next breakthroughs of high-performance large-scale meta-elements for applications.

A SuperK white light fiber-coupled laser source serves as an ideal and flexible characterization tool for achromaticity validation testing in such cases, providing predictable optical characteristics at all wavelengths to be tested and thus helping to ensure dependability among the results.

References

[1] Principles, Functions, and Applications of Optical Meta-Lens

[2] Meta-optics achieves RGB-achromatic focusing for virtual reality

[3] Inverse design enables large-scale high-performance meta-optics reshaping virtual reality

[4] Large area metalenses: design, characterization, and mass manufacturing

The SuperK advantages

Our SuperK supercontinuum white light lasers are ideal for the characterization of advanced optical components, metamaterials, plasmonics, etc.

They are as broad as a lamp and as bright as a laser. They deliver high-brightness diffraction-limited light across the entire 390-2400 nm region. You can turn it into an ultra-tunable laser by adding one of our filters.

They are maintenance-free and the monolithic fiber architecture ensures excellent reliability and a lifetime of thousands of hours.