Ready, set, go! Teamwork at its best

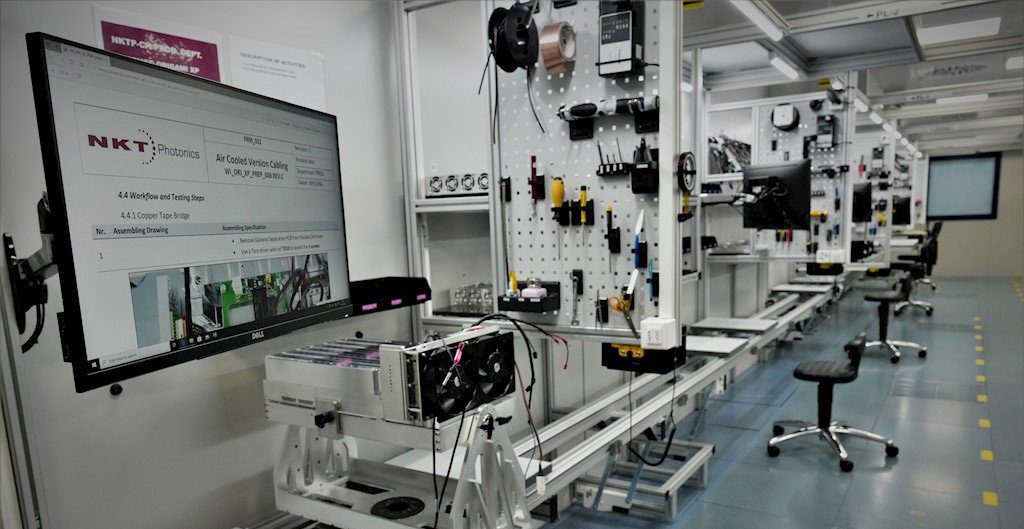

Our Swiss team is happy these days, and for good reasons; the new ORIGAMI XP/S laser assembly line just opened. In Q1, they sat down and drew up the plans. They gathered input from all stakeholders, and, in Q2, they began the hard work.

The old lab was torn down. Imagine the surprise when the team found an outdated industrial vacuum cleaner under the floor… and the joy when a team member got to use a 1-meter long drill on one of the walls.

They managed to completely renovate and set up the new production line in three short months. All thanks to the focus and dedication of the team.

Lean principles and quality assurance

The brand-new production line is based on lean principles to allow fast ramping and flexible adjusting to demand, giving the best production conditions for our ultrafast high-power laser system.

The production line is ISO 9001 and ISO 13485 qualified, to ensure the renowned high quality as always.

The renovation in 48 seconds

About the ORIGAMI XP/S

The ORIGAMI XP/S was designed for easy and cost-effective integration. It comes with removable handles and offers full remote control capabilities. A simple through-hole mounting system and high precision mechanical referencing planes ensure straightforward drop-in installation.

Benefit from clean, ultrashort pulse duration, superior beam quality, and unprecedented beam pointing by virtue of monolithic system design.

It sets new standards for all-in-one femtosecond lasers in medical device manufacturing and ultra-high precision micromachining applications.