As medical devices develop and get smaller, the ability to make high-quality cutting and fine features become more important.

With high peak-power ultrafast lasers, you can make high-quality fine features without any thermal effects.

In recent years, the use of ultrafast lasers to fabricate polymer medical devices has gained wide acceptance due to the lasers’ ability to create fine, precisely machined features and markings. Unlike mechanical methods of polymer cutting, a laser cut is a non-contact process without any tool wear which ensures a consistently high-quality cut. The transition from mechanical processing to laser machining was primarily driven by the need to create very small precise features at a high yield and lower cost.

Cut and mark in one process

Ultrafast lasers can process a wide variety of polymers, regardless of transparency or thickness. You can use the same laser to cut fine features and to produce permanent, high-quality marks. This way, you simplify manufacturing since one laser can do more than one process. The high-quality cutting and marking eliminate the need for post-processing and reduce the overall manufacturing cost.

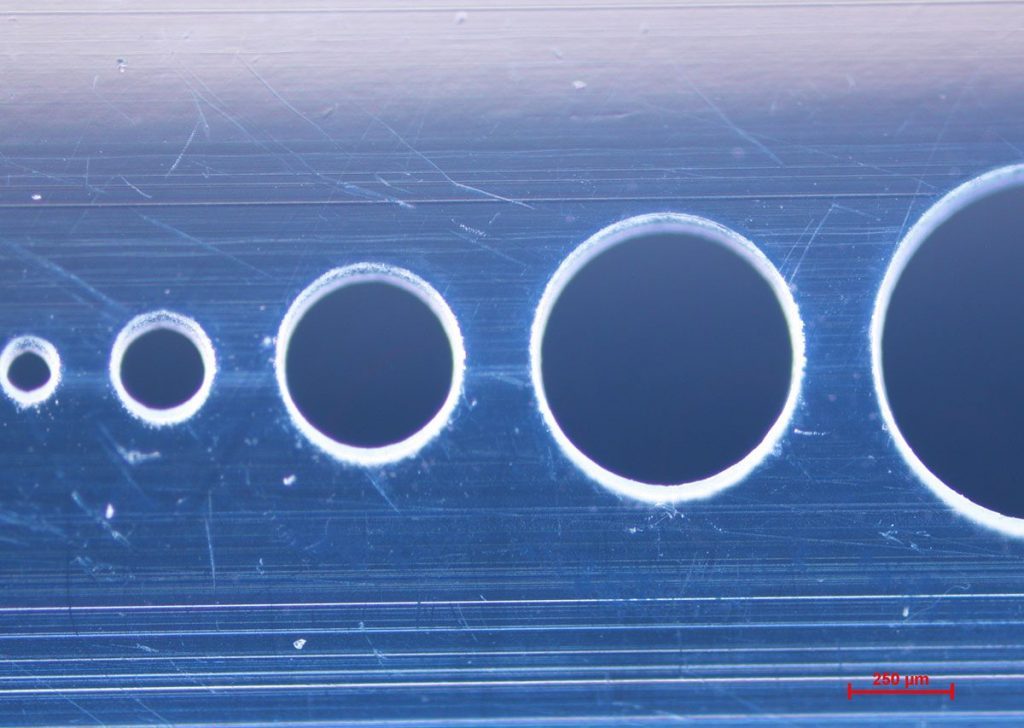

Cold ablation ensures precise, debris-free features

The duration of laser pulses has a dramatic effect on laser cutting results. When the pulse-duration is below some tens of picoseconds, the laser-material interaction enters the “cold” or “athermal” ablation regime. The cutting quality significantly improves by breaking down the material instantly in a precise manner, while the surrounding material is unaffected.

In our applications lab, we have demonstrated the cutting of various polymer tubes using our ORIGAMI 10XP femtosecond laser.

Nylon tubing is ideal for medical devices because it is lightweight, corrosion and abrasion resistant. It can withstand repeated stress over extended periods. Its strength, crush, cracking and tear resistance makes nylon perfect as the outer jacket of catheters.

Typical uses: Structural heart, peripheral, general medical, endovascular, cardiovascular, cardiac rhythm management/electrophysiology.

Polyimide tube

Polyimides are a family of high-performing polymers. They are particularly known for their mechanical performance and their chemical resistance.

Polyimides exhibit exceptional thermal stability throughout high and low temperatures and excellent insulating performance through a range of environments and frequencies. In addition, they are also known for their high strength and exceptional tensile strength.

These properties, and more, have led to widespread use of polyimide in the medical, aerospace, automotive, and electronics industries. Since polyimides are fully biocompatible, polyimide tubing can be used for both vascular and urinary catheter constructions. With its extremely small sizing capabilities, polyimide tubing can be produced to reach the smallest sized vasculatures while retaining strength and rigidity.

Typical uses: Polyimide tubing with its small sizing capabilities can be used for both vascular and urinary catheter construction.

Polytetrafluoroethylene (PTFE) liners are commonly used at the heart of catheters. The combination of extremely thin walls and the material’s superior lubricity make it the ideal material for catheter liners.

PTFE is a good fit for the medical industry; it offers usage up to high temperatures, superior non-stick properties due to its low coefficient of friction, good abrasion resistance, chemical inertness, out-standing dielectric stability, and excellent wear resistance.

Typical uses: Cardiovascular, endovascular, structural heart, cardiac rhythm management / electrophysiology, peripheral, general medical.

Summary

The ultrashort pulses delivered by our ultrafast laser are well suited to precision cutting of polymer tubes.

The Origami XP is the first all-in-one, single-box, microjoule femtosecond laser on the market. The laser head, controller and air-cooling system are all integrated in one small and robust package, with a footprint so small it even fits into a hand-luggage!

The ORIGAMI system is based on a compact monolithic chirped pulse amplification platform capable of delivering up to 70 μJ pulse energy at 1030 nm, a 5 W average power, and a pulse duration below 400 fs.