Polyimide (or PI or Kapton) is a thin film widely used in the medical and microelectronics industries due to its mechanical strength, electrical insulation, thermal stability, chemical inertness, and biocompatibility.

Ultrafast lasers provide the needed precise, non-contact micromachining processing technique with a minimal need for post-processing.

Good for medical and microelectronics industries

Polyimide (or PI or Kapton) is widely used in the manufacturing of microelectronic components for the semiconductor, computer, automotive, aerospace, and display industries. It is popular due to its mechanical strength, electrical insulation, and thermal stability. In microelectronic components, polyimide is used in wafer carriers, test holders, hard disk drives, electrical connectors, wire insulators, flexible printed circuit boards, digital copier and inkjet printer components. Due to its chemical inertness and biocompatibility, polyimide is used increasingly in medical applications such as the manufacturing of cardiovascular catheters, retrieval devices, push rings, marker bands, angioplasty, stent delivery devices, neurological devices, and drug delivery systems.

Increase miniaturization and avoid post-processing

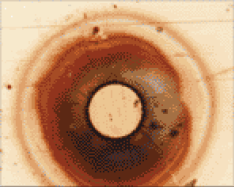

If you work in the semiconductor or medical device industry, you know the importance of manufacturing lighter, smaller, higher-density, and higher-functionality products to meet market demands. You need to find ways to make a wide range of tiny and precise features. In the early days, nanosecond pulse-width ultraviolet (UV) lasers made it possible to create small precise micron-size features in polyimide film. However, the big drawback of long nanosecond pulse UV lasers is the black carbon shoot debris that is generated around the ablated machined features1.

Two challenges are

1) it is necessary to post-process the sample to remove the surface debris which adds to the overall cost

2) there is a limit to how closely you can machine two features, which limits the density of features and the degree of product miniaturization.

It is well-known that ultrafast femtosecond laser pulses ensure clean debris-free metal removal. We wanted to explore if our ORIGAMI ultrafast laser could perform equally debris-free machining when it came to the ablation of polyimide film.

Trepanning using IR and green wavelength lasers

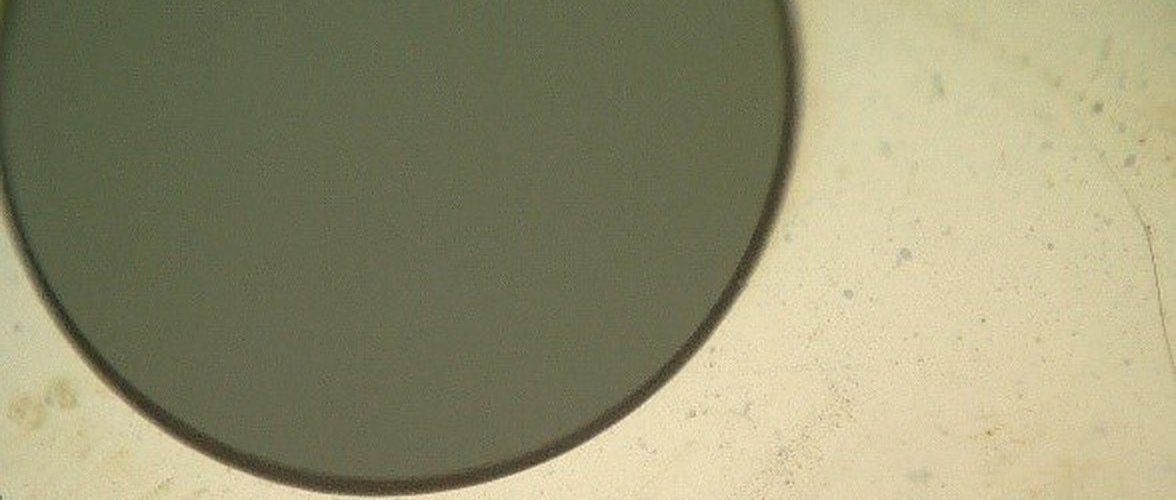

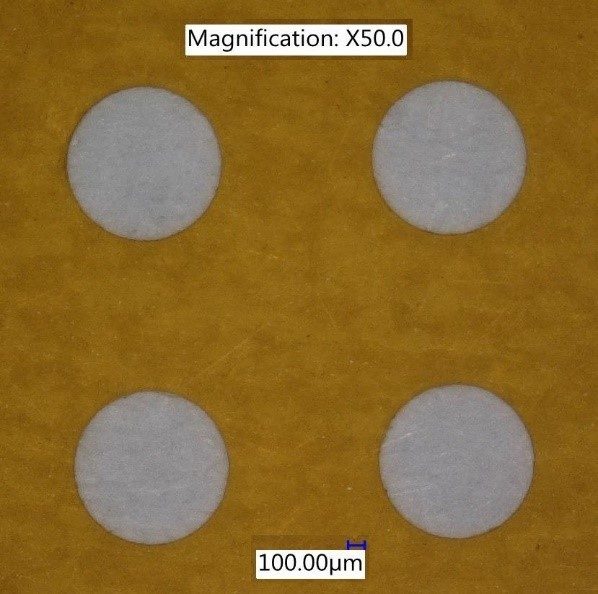

The first set of experiments was conducted using our ORIGAMI IR wavelength laser. With a multi-pass process, we trepanned large 1 mm diameter holes in a 25 µm thick polyimide film using a 20 µm diameter focused laser beam.

We observed a large decrease in debris-generation compared to nanosecond pulse UV laser machining. The high peak-power of the femtosecond laser pulse pulverizes the material instantly and leaves the surface debris-free.

So, if you want to decrease debris-generation during machining of polyimide, one of the ways is to use a high peak-power femtosecond laser.

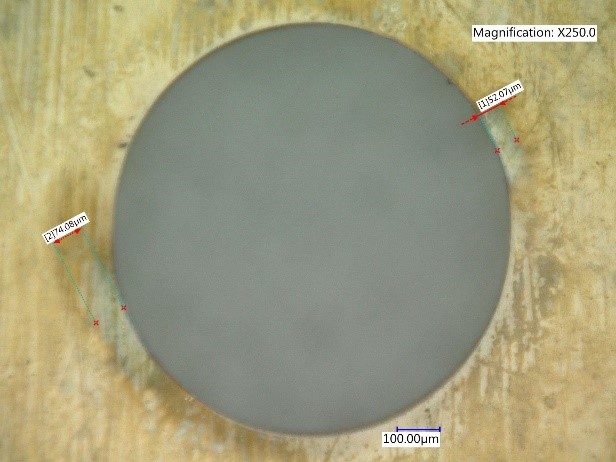

Upon further higher-magnification inspection of the holes, we did observe a small heat-affected zone (HAZ) of ≈ 52 to 74 µm around the edges of the hole.

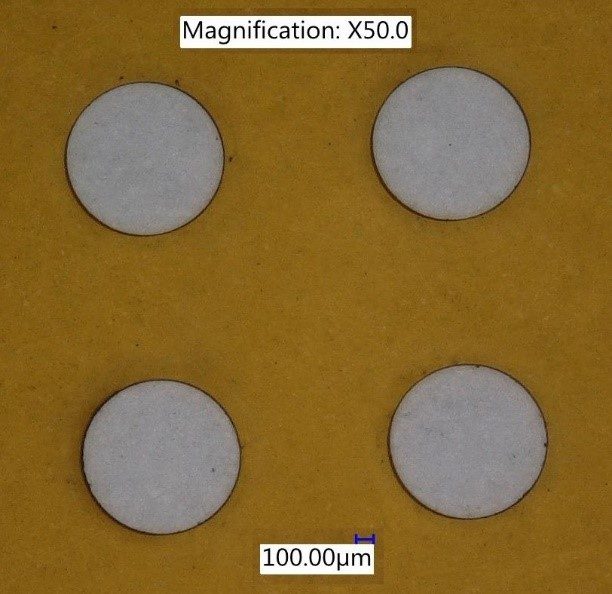

We extended our study further to explore the reduction of HAZ in polyimide machining using a green wavelength laser.

A multi-pass trepanning hole drilling using a green wavelength ORIGAMI laser gave us holes with virtually no HAZ

We verified the debris-free surface by higher-magnification inspection and confirmed non-existent HAZ as shown in Figure 5.

Conclusion

Our results indicate that our ORIGAMI femtosecond laser can be used to achieve a debris-free no-HAZ machining of polyimide film. The higher peak power of femtosecond laser pulses indeed helps to vaporize polyimide film instantly, leaving a debris-free surface.

Summary

Our results demonstrate that femtosecond pulses, delivered by our ultrafast lasers, are well suited for debris and HAZ free micromachining of polyimide film.

The ORIGAMI XP is the first all-in-one, single-box, microjoule femtosecond laser on the market. The laser head, controller and air-cooling system are all integrated in one small and robust package, with a footprint so small it even fits into a hand-luggage!

The ORIGAMI system is based on a compact monolithic chirped pulse amplification platform capable of delivering up to 70 μJ pulse energy at 1030 nm, a 5 W average power, and a pulse duration below 400 fs.