The development of femtosecond lasers has transformed the micromachining technology. It enables machining of thin, transparent and semi-transparent materials with high precision and quality at high speed.

Femtosecond lasers offer a reliable method for producing cuts, holes, and scribes in brittle materials.

Ultra-short pulses and very high peak powers

Thin glass is widely used in photonics, microelectronics, displays, and biomedical chip manufacturing and has created a need for a reliable high-yield high-quality glass machining process.

Earlier, laser processing of glass was a very low-yield process due to the long pulses that caused thermal damage. Today, femtosecond lasers provide ultra-short pulses with very high peak powers that allow for

surface and internal bulk material modification of thin transparent materials.

An ultra-short pulse delivers energy at a time scale shorter than the electron-phonon coupling processes in any material.

The ultra-short pulse width suppresses the formation of the heat affected zone and thermal damage. This results in high-precision and high-resolution processing through a cold ablation regime – with unrivalled process reliability.

A tightly focused beam enables very high-resolution micro-machining of complex shapes at micro-scales.

Glass cutting

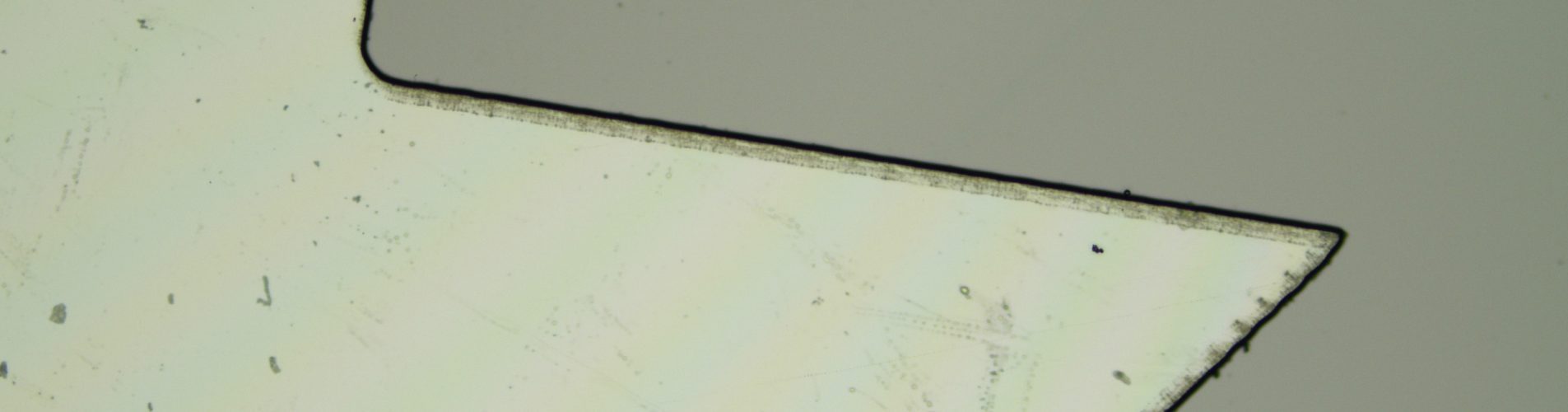

In our application lab, we have demonstrated cutting of 50 and 100 µm thin AF 32® glass by ablation, using our infrared ORIGAMI XP laser. Figure 1 shows cuts with very clean-cut edges. There is no thermal damage or cracks as typically seen with long-pulse lasers.

In contrast to machining achieved by internal modification of glass, known as “stealth” laser machining, the ablation process is overall faster and provides more flexibility for cutting various closed shapes, such as circles.

Glass Scribing

The high growth in the manufacturing of thin, flexible displays for mobile devices has driven investment into new thin glass cutting and dicing techniques. In one such technique, known as scribe and break, glass is scribed using lasers.

Glass scribed using ultrafast lasers provides a more consistent and predictable breaking process with straighter-cut edges and higher yield.

In our application lab, we have shown clean scribes of 20 µm depth in a 50 µm thin glass, as shown below. The cross-section profile shows an ideal clean V shape without any cracks that is optimal for the subsequent breaking process.

Glass drilling

Lasers provide a non-contact and clean hole drilling technology that allows drilling of small holes by percussion as well as trepanning technique.

In our application lab, we have drilled very small 15 µm diameter holes in 100 µm thick glass, using our infrared ORIGAMI XP laser. Drilling of even smaller holes is possible using our green ORIGAMI XP laser.

Summary

Our results demonstrate that femtosecond pulses, delivered by NKT Photonics’ ultrafast lasers, are well suited for micromachining of thin glass.

The ORIGAMI XP is the first all-in-one, single-box, microjoule femtosecond laser on the market. The laser head, controller and air-cooling system are all integrated in one small and robust package, with a footprint so small it even fits into a hand-luggage!

The ORIGAMI system is based on a compact monolithic chirped pulse amplification platform capable of delivering up to 70 μJ pulse energy at 1030 nm, a 5 W average power, and a pulse duration below 400 fs.