For more than 20 years, NKT Photonics has been making special optical fibers, called Photonics Crystal Fibers, and lasers based on those fibers.

What are optical fibers?

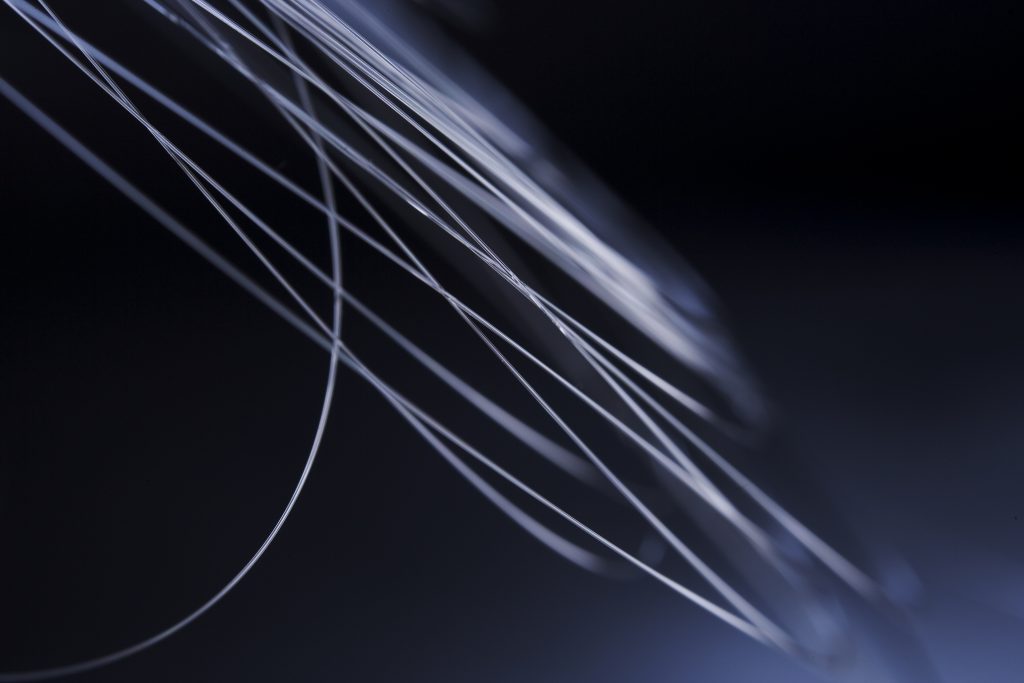

An optical fiber is a long, thin strand of material designed to transmit light signals over long distances. It is usually made of glass or plastic.

The fiber consists of two parts: A center part called the core and a protective outer part called the cladding. The light travels through the core, and the cladding helps keep the light inside the fiber.

The core is made of a material with a higher refractive index than the cladding. When light enters the core, it is reflected internally and bounces off the walls inside the fiber. This bouncing, called total internal reflection, allows the light to travel through the fiber.

One of the greatest strengths of optical fibers is their ability to transmit information – light signals – over long distances at very high speeds. These light signals can carry a vast amount of data, such as phone calls, internet data, or even television signals. However, they can also be used as the core medium in fiber lasers – which is how most people use our fibers (see the section on fiber lasers below).

What is a Photonic Crystal Fiber?

NKT Photonics specializes in a type of optical fiber called Photonic Crystal Fibers (PCFs). PCFs, also known as holey fibers or micro-structured fibers, have a unique structure that allows for precise control of light propagation. They are designed to exploit the properties of periodic microstructures or “holes” running along the length of the fiber.

The core innovation of PCFs is the distribution of air holes or voids within the fiber’s cladding. These holes form a periodic pattern, creating a photonic crystal structure. The pattern and distribution of the holes can be precisely engineered to control the behavior of light within the fiber.

PCFs have several advantages compared to traditional fibers like those used for telecommunication. We can design PCFs to exhibit specific optical properties that are difficult to achieve with traditional fibers. For example, PCFs can be engineered to have large mode areas, enabling efficient power handling in high-power laser applications. They can also support single-mode operation over a wide spectral range, making them useful for applications that need precise and stable light transmission.

The unique structure of PCFs facilitates strong nonlinear interactions between light and matter. This allows for efficient nonlinear processes, such as supercontinuum generation, where a single input at one color is converted to white light while maintaining its laser properties.

What is a laser?

A laser is a special device that produces a very focused and powerful light beam. It works using a process called “stimulated emission of radiation.”

Imagine light as a group of tiny particles called photons. In a regular light source, like a light bulb, photons move in different directions, creating scattered and less intense light.

In a laser, the photons are all “lined up” and travel together in a specific direction. This is achieved using a gain medium – a solid, liquid, or gas – that can amplify and direct the light.

Inside the laser, there are generally two mirrors placed at opposite ends. One mirror is partially reflective, allowing some light to pass through, while the other is fully reflective, bouncing all the light back into the medium. This creates a feedback loop where the light keeps bouncing back and forth.

When energy is added to the medium, through an electrical current or another light source, it excites the atoms or molecules in the medium. The excited particles release photons, and as they bounce back and forth between the mirrors, they stimulate other excited particles to release more photons that are in phase with the original photons. This is called stimulated emission.

This process builds up a concentrated and coherent beam of light, with all the photons in step with each other. The light beam that emerges from the partially reflective mirror is a laser beam. It has a specific wavelength (color) and is very intense and focused.

What is a fiber laser?

Most NKT Photonics lasers are fiber lasers. A fiber laser is a type of laser that uses an optical fiber as the gain medium. Unlike traditional lasers that use a solid, liquid, or gas as the gain medium, fiber lasers use a specially designed optical fiber to generate and amplify the laser light.

The core of the optical fiber in a fiber laser is doped with rare-earth elements such as erbium, ytterbium, or thulium. These dopants give the fiber the necessary properties to efficiently amplify light signals. When energy is applied to the fiber, typically through a pump laser or diode, the dopants in the fiber become excited and release photons.

The photons bounce back and forth within the fiber, undergoing stimulated emission and amplifying the light. The core of the fiber is designed to confine the light within it, allowing for a longer interaction length and better amplification. The amplification process is similar to what happens in other lasers, but you get several advantages by using an optical fiber as the gain medium.

One significant advantage of fiber lasers is their high power and beam quality. The fiber’s design allows for efficient heat dissipation, which enables them to produce high-power laser beams without significant thermal issues. Fiber lasers generate laser beams with excellent beam quality, meaning the light is tightly focused and has a well-defined shape and direction. This makes fiber lasers suitable for applications that need precise and controlled laser beams.

Finally, fiber lasers are exceptionally robust and reliable because all the light in the laser is confined within the optical fibers. Consequently, this type of laser is preferred in applications where up-time and low maintenance is a priority, such as the semiconductor industry.

What is a supercontinuum laser?

One of NKT Photonics’ most well-known products is the supercontinuum laser. Most lasers produce light of a specific color or wavelength. But a supercontinuum laser is designed to generate a wide range of colors simultaneously. It does this using NKT Photonics’ unique Photonic Crystal Fiber, PCF.

Inside the PCF, the laser light is carefully guided and interacts with the fiber’s structure. This interaction causes the light to spread out and break up into many different colors.

The result is a laser beam that contains a continuous spectrum of colors, from ultraviolet to infrared. The spectrum is called a “supercontinuum” because it covers a broad range of wavelengths in a continuous and smooth manner, unlike the discrete lines of color from a regular laser.

Supercontinuum lasers have many useful applications. For example, they are used in scientific research for spectroscopy, where different substances can be identified by the unique way they interact with different colors of light. They are also used in bio-medical imaging, semiconductor inspection, and optical device characterization.

See all our supercontinuum lasers.

What is a single-frequency laser?

Single-frequency lasers are almost the exact opposite of supercontinuum lasers. A regular laser sends out light that consists of a few colors, only. It may look like only one color, but the output is smeared over a certain range of colors. A single-frequency laser is designed to produce light of a very specific color or wavelength with extremely tight tolerances.

If you look inside a single-frequency fiber laser, you’ll see special components (called fiber Bragg gratings) that make sure the laser only produces light at a precise frequency. These components act like a filter, allowing only one color to pass through while blocking other colors. The result is a laser beam that consists of only one specific color. It’s like playing a single note on a piano, producing a pure and focused sound.

Single-frequency lasers are used in important applications in various fields. For example, they are used in high-precision measurements and fiber sensing because their single-color light can interact with substances in a particular way, allowing for precise analysis.

This laser type is also used in quantum applications, e.g., to manipulate single atoms in a vacuum chamber, such as those used in a neutral atom quantum computer. Here, different types of single-frequency lasers at different wavelengths (colors) are used to trap, cool, and manipulate the quantum state of the individual atoms. The lasers are not part of the quantum computer as such, but rather the tool used to control the atoms forming the qubits. Qubits, or quantum bits, are the basic building blocks used in quantum computing.

If the single-frequency lasers are amplified to sufficiently high power, they can also be used in directed energy applications, where a beam of high-power light (typically several kWatt) is aimed at a target to disable it. NKT Photonics lasers are primarily used in developing drone defense systems. Customers combine our lasers with a range of other equipment to target and disable small drones attacking, e.g., a ship or a vehicle.

See the single-frequency lasers.

What is an ultrafast laser?

While many types of lasers, like those used for quantum technology for example, emit light in a constant stream, ultrafast lasers produce incredibly short bursts of light. These bursts are emitted thousands or even millions of times per second. Consequently, the individual pulses of light are extremely short with a duration in the femtosecond (one quadrillionth of a second) or picosecond (one trillionth of a second) range, delivering high amounts of energy in a very short time.

Ultrafast lasers are used in many important applications. For example, they are used in scientific research to study ultrafast phenomena in physics, chemistry, and biology. These lasers can reveal the dynamics of chemical reactions, help understand how molecules interact, and investigate processes happening at the atomic and molecular levels.

They are also used in material processing, such as precision cutting or drilling, where ultrafast pulses can remove the material with high precision and minimal damage to the surrounding areas.

Finally, they are used in delicate surgery, such as cataract surgery in the eyes, where accurate and fast pulses provide extreme control and precision of the cut. The high preciseness reduces the risk of complications and improves the general outcome of the procedures.

See our femtosecond lasers and our ultrafast fiber lasers.

Message us

And we will get right back to you (for support and RMA requests, please use our support contact form)

"*" indicates required fields