Every year, apples, pears, and blueberries alone account for a EUR 6.1 billion loss globally. The fruit waste also contributes hugely to greenhouse gas emissions because fruit emits methane as it decomposes.

If we could monitor stored fruit continuously, we could prevent as much as 50% of the storage losses.

It is not easy to preserve and store fresh fruit

Fruit owners keep the fruit in large storage facilities. They typically store hundreds of tons of fruit in one room, and they often have 10 to 20 rooms. That’s a lot of fruit to keep track of.

The fruit is stored in a controlled temperature and atmosphere to extend its lifetime. But it is all about balance. If the oxygen level in the storage rooms is too high, the fruit will decay. However, if it is too low, the fruit will start to ferment.

The key is to keep a close eye on all the gasses that influence the fruit, such as oxygen and carbon dioxide. The owner can optimize the storage conditions by controlling the oxygen and carbon dioxide levels.

The level of methanol and ethanol tells the owner of beginning fermentation, rot, or fungal infections. Knowing this, the owner can either adjust the storage conditions or sell the fruit before it goes bad.

The real-time multi-gas detector that saves fruit

Under Horizon2020, a European consortium is making a new weapon in the fight against fruit waste.

The consortium is called MAX-FRESH. It aims to commercialize a sensor that can – simultaneously and in real-time – detect low levels of several volatile gases that indicate ripening, fermentation, damage, or rotting of the stored fruit.

Such a system needs a cool name and an abbreviation, so we proudly present the Interactive Storage System-Monitor or the ISS-Monitor!

The ISS-Monitor regularly samples the air in the storage rooms and analyzes it.

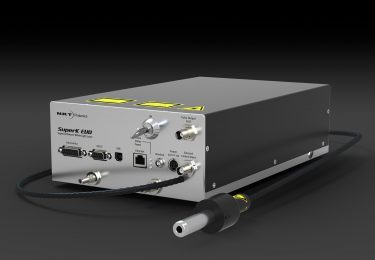

The central analysis unit is our mid-IR supercontinuum white light laser and a spectrometer. The equipment determines the concentration of the gasses in the storage room using gas spectroscopy.

The fruit owner will get an alarm if the ISS-Monitor detects harmful conditions and can decide to change the storage conditions or sell the fruit.

According to the project description, the ISS-Monitor can potentially reduce the losses of stored fresh food by 50%, extend storage life by 20%, and reduce post-harvest chemical treatments by 50%.

This contributes to fulfilling the UN’s Sustainable Development Goal Target of halving food waste by 2030 as well as the EU’s targets to reduce food waste across the EU by 2023.

Commercialization of an existing prototype

The MAX-FRESH team is building a commercial version of the ISS-Monitor based on a functional prototype that was developed and tested during the QCAP project and funded by InterReg North-West Europe.

The ISS-Monitor will be commercially available in 2023.

Who are these fruit ninjas?

The MAX-FRESH project team is brought together to combine cutting-edge technologies with unique expertise and consists of an academic partner and three market-leading industrial partners:

Get the overview in 90 seconds

Do you want to learn more?

- MAX-FRESH project description: Maximizing freshness and minimizing losses of agriculture products through automated atmosphere management in storage facilities.

- QCAP project description: Real-time “interactive storage” quality control in fresh agro products (QCAP).

- Summary from Catalyze: MAX-FRESH: Tackling food waste with a revolutionary fresh food monitoring system.