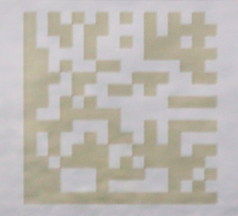

The high peak powers produced by femtosecond laser pulses allow successful precise laser sub-surface marking within transparent materials, such as glass.

This is important in applications where product traceability, product branding, and more importantly, anti-forgery require tamper-free and permanent marks. Sub-surface marking renders the actual surface uncompromised and debris-free.

The contrast of the marks can be made high or subtle by fine control of the laser processing parameters. Typically, surface marking of glass is achieved using ns pulses at 1064 nm, such as CO2 or fiber lasers.

These lasers mark the glass material by generating fractures at the surface. When using long pulse lasers (ns), thermal reactions form micro-cracks, the marking becomes visible. Other methods employ single-photon green or UV ns lasers, but this can still lead to unwelcome thermal effects which can compromise the desirable properties of the glass.

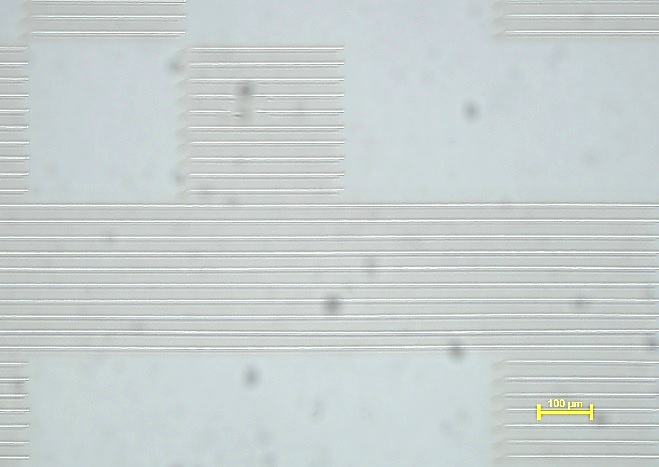

Transparent materials are notoriously difficult to mark using conventional lasers. Such markings produce debris when machining the surface. By focusing a 1030 nm femtosecond beam tightly into the bulk of the glass, it is possible to absorb multiple photons leading to a highly localized mark inside the glass lattice with negligible heat input.

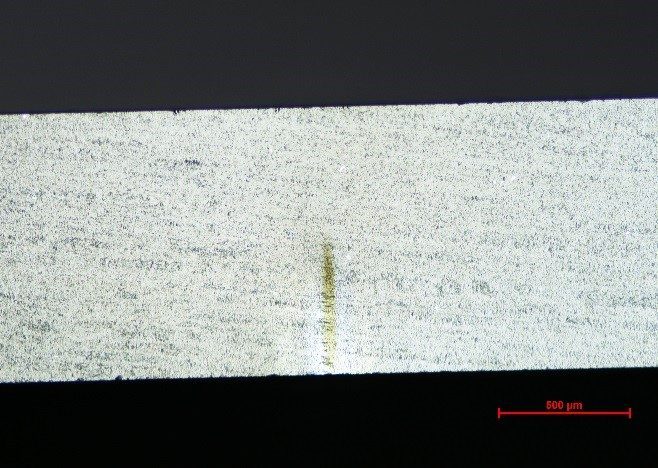

Very small features can be achieved inside the glass lattice and the surface remains unaffected, making the marks impervious to chemical cleaning. The short pulse widths ensure that the thermal load into the sample is virtually inconsequential, so chipping and fracturing of the sample are insignificant.

The interaction of the laser with the glass lattice produces permanent structural modification by altering the refractive index that gives rise to a contrast marking which can be seen by the eye. Since the mark exists under the surface, it cannot be removed or altered.

It is essential to focus the beam to a small spot size within the glass to avoid surpassing the damage threshold fluence on the surface. Marking of inside the crystal requires fine adjustment of the focus position combined with small spot sizes to reach a fluence that surpasses the damage threshold inside the desired area of the crystal.

By focusing the beam tightly, it is possible to control the depth of the marking whilst ensuring that the fluence at the surface is not above the damage threshold in unwanted planes.

Conclusion

In our applications lab, we have demonstrated the sub-surface marking of glass slides using the ORIGAMI 10XP femtosecond laser. The clean soliton-like femtosecond pulses ensure precision delivery of peak power to create the internal marks and the excellent beam quality of the laser ensures a tightly focused spot, allowing good depth control of the mark’s location. By adjusting the pulse spacing or number of passes, it is possible to enhance the contrast for a more readable mark, or where needed, to produce a more subtle mark for anti-counterfeit applications.

Summary

The ultrashort pulses delivered by NKT Photonics’ ultrafast laser range are well suited to producing sub-surface marks in glass. This was demonstrated successfully with the ORIGAMI 10-XP laser.

ONEFIVE ORIGAMI XP

The ORIGAMI XP is the first all-in-one, single-box, microjoule femtosecond laser on the market. The laser head, controller and air-cooling system are all integrated in one small and robust package, with a footprint so small it even fits into a hand-luggage!

The ORIGAMI system is based on a compact monolithic chirped pulse amplification platform capable of delivering up to 70 μJ pulse energy at 1030 nm, a 5 W average power, and a pulse duration below 400 fs.