Polyethylene terephthalate (PET) film is a clear, strong, and lightweight material.

It is becoming a popular substrate in the consumer electronics industry for manufacturing flexible microelectronics circuits and displays due to its transparency, high tensile strength, thermally stability, electrical insulation and chemical resistance properties.

Compared to glass and other flexible substrates, PET is a low-cost solution. Maybe you know PET as Mylar, Melinex, or Hospaphan?

Low-cost, low-weight, and high flexibility

The use of flexible substrates significantly reduces the weight of flat panel displays and provides the ability to conform, bend, or roll a display into any shape. It opens the possibility of fabricating displays by continuous roll processing, making mass production highly cost-effective. In some cases, it even allows printing circuits onto the substrate instead of using an expensive physical material deposition process.

Avoid thermal load

As displays are getting thinner and lighter with higher functionality, they demand the fabrication of precise small features. Laser micromachining is an ideal solution to create such tiny precise features in any material. One of the main challenges in laser machining of PET film is its low glass transition temperature of 78°C. It is essential to avoid any process that adds thermal load into the material and form blisters that can deform the material significantly.

It is not possible to machine PET film using long pulse nanosecond lasers due to the thermal load that long pulses deliver to the material. Ultrafast femtosecond lasers, on the other hand, provide a non-thermal cold ablation process due to their short pulses with high peak power, which makes them ideal for the micromachining of PET film.

High-quality micromachining of PET film

In our application lab, we studied the cut quality of PET films, using our ORIGAMI XP femtosecond laser.

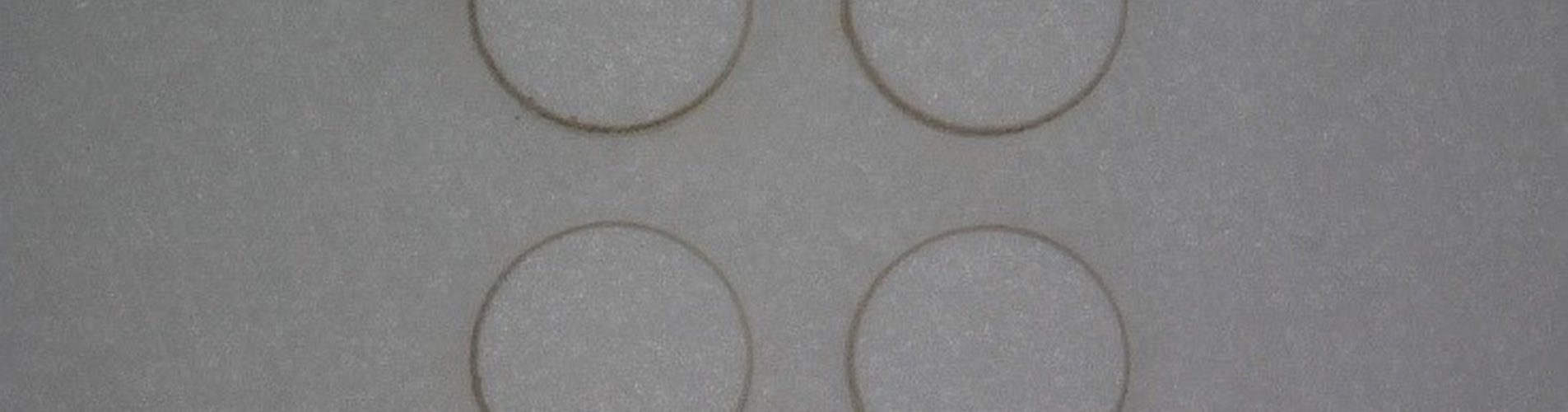

Figure 1 shows a thin 75-micron PET film micro-machined using our ORIGAMI XP femtosecond laser. We created an 800-micron diameter multi-pass trepanned-drilled array of holes using the infrared wavelength.

As expected, we achieved a clean-cut hole in the PET film. The instant removal of material with high peak-power short pulses indeed provides a clean melt-free material removal.

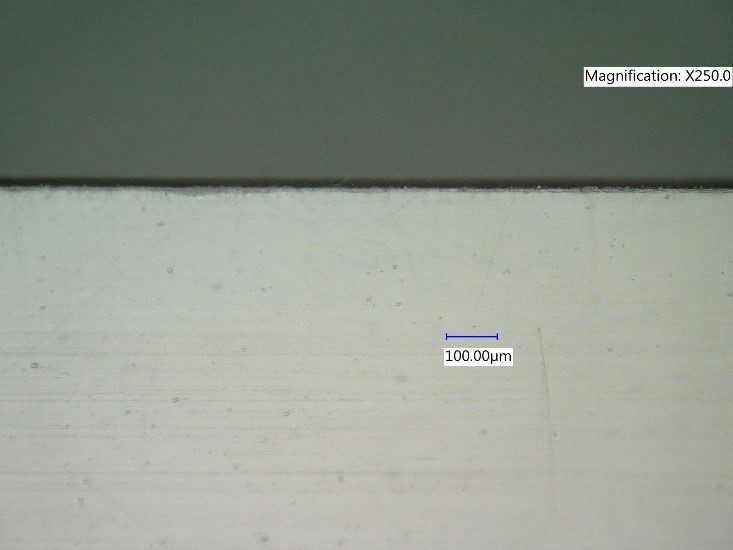

A closer evaluation of a straight-line cut, see Figure 2, shows the redeposition of loose dust near the cut edge, creating a dust zone of ≈95 microns extending from the cut edge.

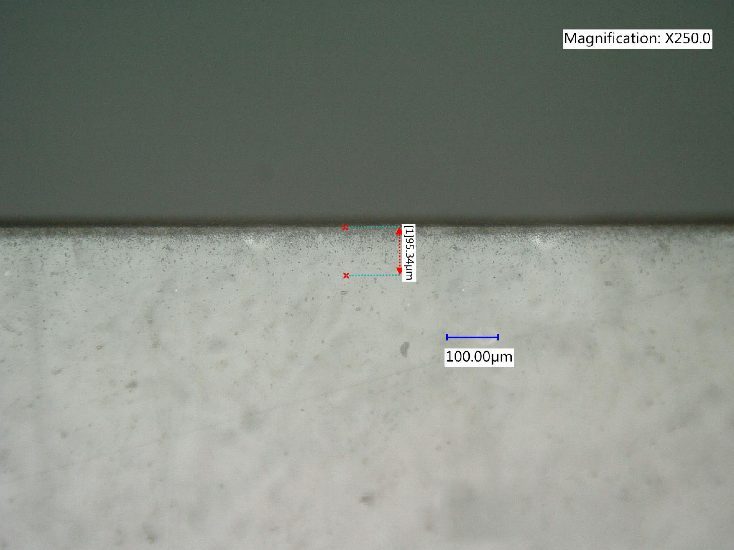

Based on our experience of machining plastic films using femtosecond lasers, we expected to achieve a better cut quality using a green wavelength laser. We made the straight-line cut, shown in Figure 3, using the ORIGAMI 05XP green laser. It did indeed show improvement in the cut quality, with a reduced dust zone of ≈29 microns.

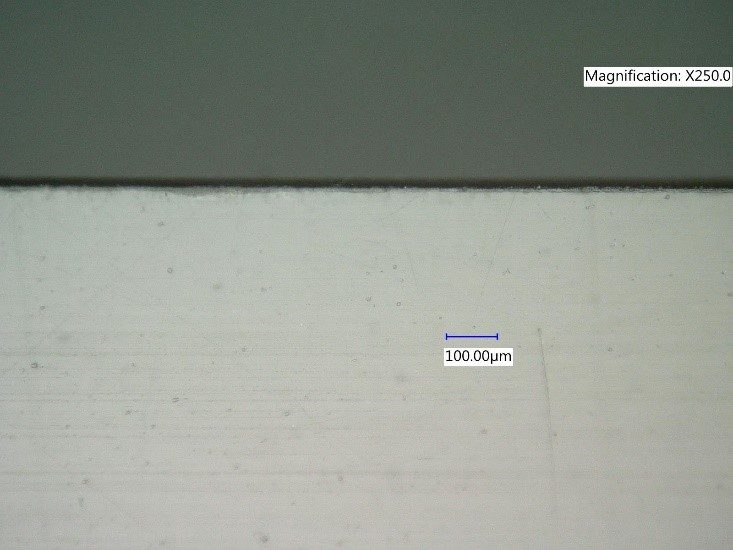

We were further able to get rid of the dust zone by simple alcohol swab cleaning. We ran an alcohol swab across the infrared wavelength cut sample surface from Figure 1. The result was a very clean cut edge, Figure 4.

Conclusion

The results show that our ORIGAMI XP femtosecond laser is well-suited to machine PET films. We have demonstrated that both infrared and green wave-lengths can process PET films with high-quality edges. A green wavelength improves the cut quality even further by reducing the dust zone. If a dust-free cut is required, a simple alcohol swab can remove any loose dust created during machining.

Summary

The ORIGAMI XP laser delivers clean, ultrashort femtosecond pulses which is ideally suited for the precise machining of thermally sensitive materials, such as PET film.

ORIGAMI XP

The Origami XP is the first all-in-one, single-box, microjoule femtosecond laser on the market. The laser head, controller and air-cooling system are all integrated in one small and robust package, with a footprint so small it even fits into a hand-luggage!

The ORIGAMI XP system used in this study is based on a compact monolithic chirped pulse amplification platform capable of delivering up to 40 μJ pulse energy at 1030 nm, a 4 W average power, and a pulse duration below 400 fs. Also available is the Origami XPS is delivering up to 5W and 70uJ at 1030nm with green and UV capability.