Since their introduction in 1986, stents have transformed the treatment of coronary heart disease.

By 1999, stent-based surgeries accounted for 84% of all percutaneous coronary interventions (PCIs). Laser cutting was used in coronary stent fabrication almost from the start.

Laser cutting with nanosecond pulsed infrared (IR) lasers easily met the accuracy requirements for large feature machining of stainless-steel stents in the early days. However, the thermal nature of nanosecond laser ablation resulted in poor cut-edge quality. This called for costly cleaning, deburring, etching, and final polishing to bring the stent’s edge quality to the level and consistency required for implantable devices.

Fine-feature demands call for ultrashort pulse lasers

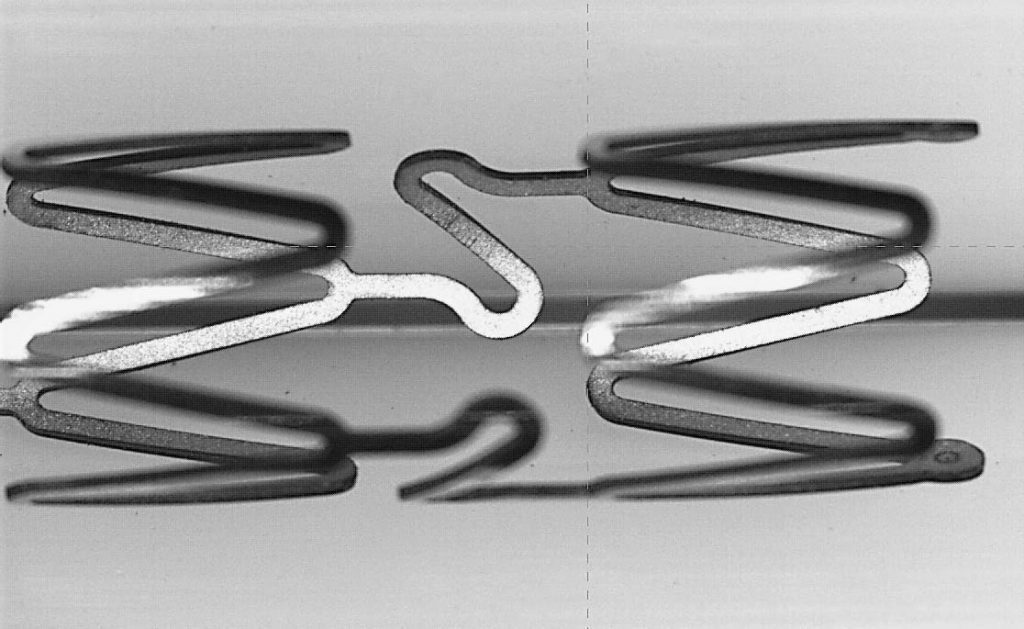

When stent material transitioned from stainless steel to nickel-titanium and then to high-strength superalloys with more challenging fine-feature requirements it became necessary to use ultrashort pulse (USP) lasers to avoid the thermal nature of machining. The migration to drug-eluting and later bioresorbable stent technology boosted the adoption of USP laser technology.

Third-generation bioresorbable stent (BRS) technology further accelerated the implementation of USP laser machining in stent manufacturing. The scaffolding in BRS technology is made from biodegradable polymers. The polymers gradually dissolve in the body making them less intrusive than metal scaffolding while helping to reduce the occurrence of blood clots and other ill effects.

High-quality USP micromachining

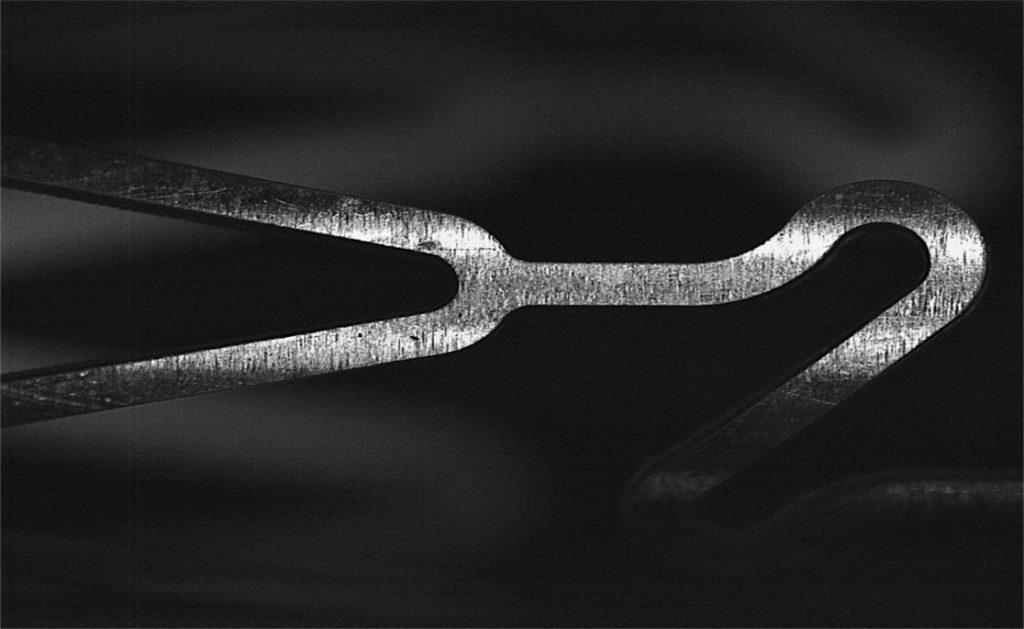

The duration of laser pulses has a dramatic effect on laser micromachining results. When pulse duration is below some tens of pico-seconds, the laser material interaction enters the “cold” or “athermal” ablation regime and the machining quality improves significantly.

While the advantages of ultrafast laser-material interaction physics are clear, the commercial viability of USP lasers was not so obvious until recently, when a robust alternative to classic Ti:sapphire gain media emerged.

At NKT Photonics we have put tremendous effort into developing the ORIGAMI XP laser – the first all-in-one, single-box, microjoule femtosecond laser on the market.

The laser head, controller, and air-cooling system are all integrated into one small and robust package, with a very small footprint.

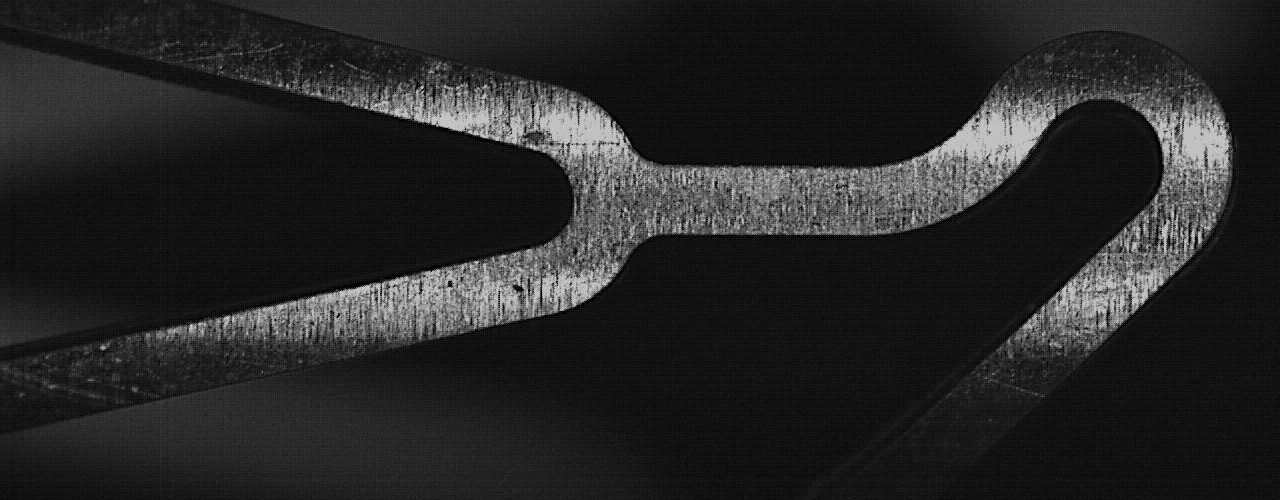

Recently, we have demonstrated cold ablation of nitinol stent cutting using an Origami XP laser and have achieved a very high cut quality.

Summary

The Ultrashort pulses delivered by NKT Photonics’ ultrafast lasers are well suited to micromachine a lot of different stent materials. Lasers are extremely reliable in creating the precise fine features demanded by today’s state-of-the-art stent designs cost-effectively.

The Origami XP is the first all-in-one, single-box, microjoule femtosecond laser on the market. The laser head, controller and air-cooling system are all integrated in one small and robust package, with a footprint so small it even fits into a hand-luggage!

The ORIGAMI XP laser is based on a compact monolithic chirped pulse amplification platform capable of delivering up to 70 μJ pulse energy at 1030 nm, a 5 W average power, and a pulse duration below 400 fs.

Download this application note as pdf.