Laser marking offers the flexibility to directly mark a range of alphanumeric characters, logos, images, or barcodes on polymers without contact with the sample.

Materials processing with ultrafast lasers provides unique advantages over conventional laser processing techniques that typically employ nanosecond and longer pulses.

Fast high-precision processing

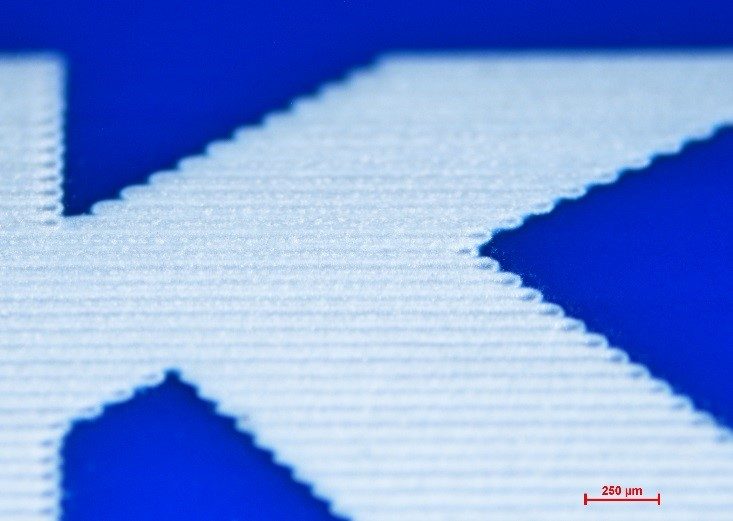

The short pulse widths and high repetition rates of ultrafast lasers allow for faster processing speeds – with high precision – giving rise to the possibility of creating incredibly small marking features compared to longer pulse durations marking.

The multiphoton absorption of ultrashort pulses means that the wavelength of the femtosecond pulses plays a less critical role and in the cold processing regime, the marks are free of melting and charring.

Nylon tubing is widely used in manufacturing of medical devices because of its lightweight, corrosion, and abrasion resistance.

High-quality marks on transparent samples

Ultrafast lasers can be used to process a number of polymers, irrespective of transparency or thickness. The same laser that can cut the material, can also produce a permanent, high-quality mark, simplifying manufacturing by enabling more than one process by a single laser. In most cases, the quality of such cuttings and markings eliminate the need for post-processing and reduces the manufacturing cost.

Marking of medical devices

At NKT Photonics we have recently completed a study of marking various polymer tubes that are commonly used in medical device manufacturing.

Polyimide is a high-performing polymer commonly used in implantable medical device manufacturing since it is fully biocompatible.

Here, a high contrast mark has been produced on a 1.7 mm diameter tube. Precise, fine features are easily achieved with ultrafast lasers.

The ORGIAMI 10XP laser can process a wide range of polymers, producing high quality and high contrast

marks that are both human readable and machine readable.

our ORIGAMI 10XP laser.

PTFE tube

PTFE is commonly used in the medical industry. It offers usage up to high temperatures, excellent non-stick properties due to its low coefficient of friction, good abrasion resistance, chemical inertness, excellent dielectric stability, and excellent wear resistance.

ORIGAMI 10XP laser.

Summary

The Ultrashort pulses delivered by NKT Photonics’ ultrafast laser range are well suited to precision marking fine features onto a wide range of polymers that are frequently used within the medical device manufacturing industry.

The Origami XP is the first all-in-one, single-box, microjoule femtosecond laser on the market. The laser head, controller and air-cooling system are all integrated in one small and robust package, with a footprint so small it even fits into a hand-luggage!

The ORIGAMI system is based on a compact monolithic chirped pulse amplification platform capable of delivering up to 70 μJ pulse energy at 1030 nm, a 5 W average power, and a pulse duration below 400 fs.